Before purchasing any pressure washer accessory, you must ensure it is compatible with your specific machine. Upgrading your fittings can also improve durability, convenience, and performance. Choosing the right fittings is essential for ensuring your pressure washer operates efficiently. This article discusses the basics of compatibility and the key factors to consider when selecting fittings for your machine.

Two things to keep in mind:

- Check Connection Type: The most common connections are M22 (threaded), Quick Connect (easiest to use), and various proprietary Bayonet Fittings (often found on electric washers like Karcher, Gerni, Bosch or Ryobi). Adapters exist, but matching the connection directly is always best.

- Match Pressure and Flow Ratings: Every accessory will have a maximum PSI (bar) and GPM (L/min) rating. Never use an accessory rated for less pressure or flow than your pressure washer’s output, as this can cause the accessory to burst or damage your pump.

Types of Fittings

The two most common connections in pressure washing are the Quick Connect (QC) fittings and the M22 threaded couplings.

Quick-Connect Fittings

The quick-connect (QC) system is a must-have upgrade that replaces standard threaded connections (like M22) with simple push-and-snap couplings. This dramatically reduces setup and tear-down time when switching between a spray gun, surface cleaner, or different lances.

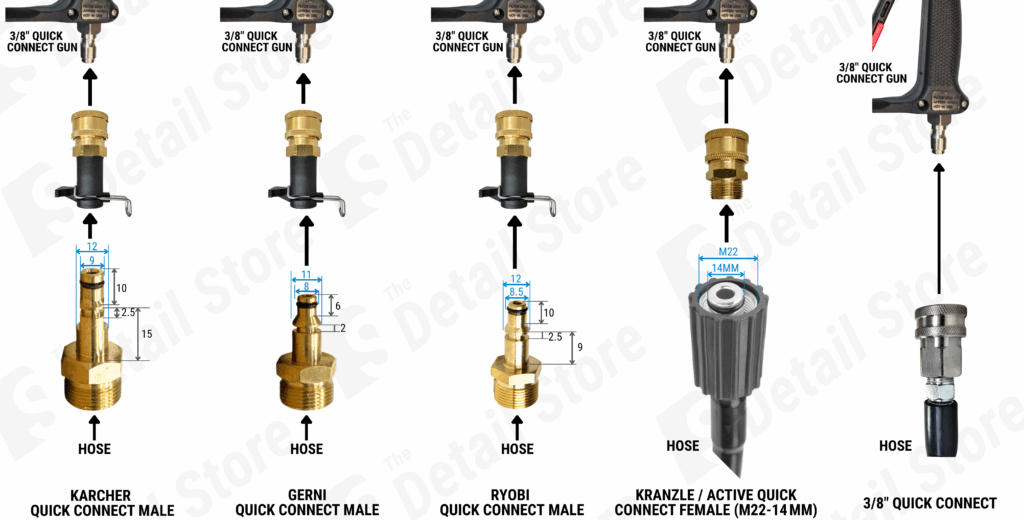

Below is a table to help streamline your fittings:

Quick connect fittings come in a range of types and sizes, but their main advantage is allowing fast, easy attachment and removal of hoses and accessories. They offer a more convenient and time-saving alternative to traditional threaded fittings, making them ideal for setups where connections need to be changed frequently.

- 3/8-Inch QC: The standard for professional/commercial high-pressure lines (hose to gun, hose to pump). It’s robust and allows for very fast attachment swaps. The CleanSkin M22 (M) to 3/8″ (F) Quick Connect Coupler is a common one used by detailers.

- 1/4-Inch QC: Primarily used for nozzles and spray tips at the end of the wand, such as the CleanSkin 1/4″ Quick Connect Coupler.

- Adapters: You can convert M22 to QC (e.g., M22-14mm Male to 3/8″ QC Female) to standardize all your equipment for fast setup and breakdown. A great example would be the CleanSkin 3/8″ (F) Quick Connect Adaptor.

These fittings allow for fast attachment and detachment of hoses and accessories, saving time during tasks like car detailing. Cleanskin Stainless Quick Connect Kit is the ideal choice for various applications.

Threaded Fittings

Threaded fittings are the standard in Australia and are known for providing a secure, leak-free connection. However, they typically require the use of thread seal tape to ensure a proper seal, which can take more time and effort. These fittings are best suited for more permanent setups, such as fixed pipelines or wall-mounted pressure washers.

A few things to keep in mind for M22 Threaded Fittings:

- M22-14mm (Most common in Australia / New Zealand): The standard on most gas-powered pressure washers and many accessories. The inner diameter of the female fitting (where the male connector seats) is 14 mm.

- M22-15mm (USA / Canada): Common on many electric-powered pressure washers (brands like Sun Joe, Ryobi, etc.). The inner diameter is 15 mm.

- The Critical Difference: A male 15mm pin will not fit into a female 14mm coupling. A male 14mm pin will fit into a female 15mm coupling, but it will not seal properly and will leak. Always measure the inside diameter of your female connection or the pin size of your male connection.

In Australia, BSP (British Standard Pipe) threads are commonly used. It’s important not to confuse these with NPT (National Pipe Thread), which is typically used in the United States, BSP and NPT threads are not compatible.

When selecting the right fittings, always check the thread size. Common sizes include 1/4″, 3/8″, and M22 x 1.4mm (with a 14mm internal diameter), which is frequently used in Australian pressure washer systems.

These provide a secure, leak-free connection but require more effort to attach. They are ideal for high-pressure applications, such as rinsing trucks or industrial equipment.

Compatibility Factors

Material Quality

Choose fittings made of stainless steel or brass for durability, as these materials are resistant to corrosion. The material of your pressure washer fittings is key to their durability and performance. Here’s a brief overview of the most common materials:

| Material | Pros | Cons |

| Brass | Most common and affordable. Good for residential and light-duty use. It’s corrosion-resistant. Good for consumer-grade washers (under 3,000 PSI). Decent resistance to rust. | Softer than steel, can wear out over time faster under very high pressure ( PSI) or temperature. Not ideal for high-pressure or frequent professional use. |

| Nickel-Plated Brass | Stronger than brass. Improved corrosion resistance and a cleaner, more professional look. | Plating can chip off over time, exposing the brass underneath, making it susceptible to rust and corrosion, especially with chemicals. Slightly more expensive than standard brass. |

| Stainless Steel 201 SS (The Budget Option) | The professional standard. Cheaper than other stainless steel grades. Very hard and strong. | Lower corrosion resistance due to less nickel. Prone to rusting and not recommended for constant exposure to water, chemicals, or humid environments. |

| Stainless Steel 304 SS (The All-Rounder) | Excellent strength and superior corrosion resistance. A great balance of performance and value for prosumer and commercial use. | More expensive than brass or 201 SS. |

| Stainless Steel 316 SS (The Ultimate Choice) | Contains molybdenum for the best corrosion resistance, especially against salt and chemicals (“marine-grade”). The most durable option. | Most expensive material. |

We recommend 304SS which is the gold standard for pressure washing which is a suitable balance between cost, and performance.

Typically over time you will notice rust formation at the ends of the pressure hose where it terminates and this is when water is left within the pressure hose, and is not fully drained after use. To prevent this, you can opt for a pressure hose with preferably 304SS internals.

Conclusion

Investing in quality fittings can enhance the longevity and performance of your pressure washer. Proper fittings improve compatibility and help reduce downtime.

-

Calvin brings a wealth of experience across multiple engineering disciplines, including chemical, mechanical, and electrical engineering. His in-depth knowledge of filtration systems and hydraulic pumps has positioned him as an expert in the pressure washer product category. With a unique combination of technical expertise and business insight, Calvin excels at solving complex challenges and driving innovation, particularly in the car detailing industry.

-

Aaron is a passionate car detailing enthusiast who channels his expertise and love for pristine vehicles into engaging blog content for a leading detail store website. With a keen eye for detail and a wealth of knowledge about the latest products and techniques, Aaron provides invaluable insights and tips to fellow car enthusiasts. His dedication to achieving showroom-quality results and his ability to explain complex processes in an easy-to-understand manner make his blog a go-to resource for anyone looking to elevate their car detailing game.